Another Polpharma API strategic milestone achieved!

KiloLab Laboratory – a development and production in a kilogram scale – has been launched, according to Polpharma API development strategy adopted in 2021.

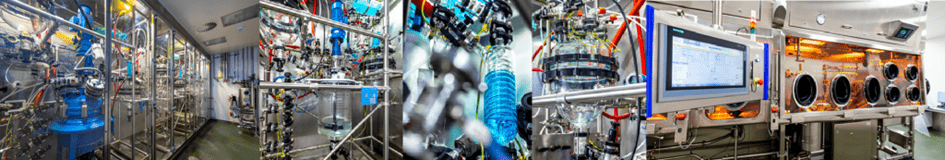

The new facility is adapted to GMP conditions and allows work with products with OEL>200 ng/m3(Highly Potent API with OEB category 5).

KiloLab has almost 120 m2 of production space and over 150 m2 of technical space with installations supporting KiloLab.

The production line includes:

1) Isolator (2 chambers: Weighing & Drying)

Drying chamber is equipped with:

- Nutsche-filter;

- Tray dryer;

- Mill with a wide range of PSD capabilities.

2) Reactors:

- Glass reactor system with a volume of 30 Liters, operating in the temperature range -400C – 2000C;

- CRYO glass reactor system with a volume of 25 Liters, operating in the temperature range -800C – 2000C;

- Enamelled reactor system with a volume of 63 Liters, operating in the temperature range -400C – 2000C;

Due to the production of HP API, all reactor systems were enclosed in RABS – a special system that increases operator safety through constant negative pressure and glove ports.

KiloLab project is another investment increasing the competitiveness and production and development capabilities of Polpharma API.

Author: Michal Sulkowski, Senior Industrial Engineering Specialist Engineering and Maintenance Department API Business Unit