A New Alliance: ICROM and PolyCrystalLine

ICROM and PolyCrystalLine SpA have announced their strategic and exclusive partnership to provide integrated solutions for chemical development and custom manufacturing of APIs.

The two Italian companies will offer their clients high-tech, integrated full-service solutions to handle challenging projects requiring various skills and technologies by merging their expertise in research, chemical development, set-up of polymorphs, tech transfer, scale-up and GMP manufacturing.

Each company will contribute to the synergy through hi-tech services, expertise and know-how.

PolyCrystalLine will be in charge of solid-state studies and related specific chemistry while ICROM will handle GMP scale-up and manufacturing of chemical and crystallization processes.

Merging high-level professionals from the two teams will ensure time efficiency, cost control and high performance leading to an overall improvement for the benefit of all clients.

The two companies

PolyCrystalLine was founded in 2005 as a start-up within the crystal-engineering group of the University of Bologna.

It has since grown into a company specialized in providing reliable solutions to optimize and control the crystallization process of active pharmaceutical ingredients for pharmaceutical companies. This mission is accomplished by the engagement of over 25 highly skilled employees.

“It is a pleasure, as CEO of PolyCrystalLine, to announce this strategic alliance with ICROM, a company that will extend our services portfolio guaranteeing the cGMP manufacturing of APIs with consistent solid-state properties,” states the CEO of PolyCrystalLine, Stefano Luca Giaffreda.

ICROM has over 50 years of experience as a chemical-pharmaceutical company focusing on the development and multi-scale GMP manufacturing of active pharmaceutical ingredients.

With up to 90 m3 reaction capacity and 85 employees among R&D, operations, quality and regulatory, finance, and marketing, the company delivers its products and services to more than 40 countries worldwide and supports the global pharmaceutical segment both as a CDMO for new chemical entities and by delivering high quality APIs to the generic drug market.

“We are proud to announce the creation of a strategic hub, where ICROM and PolyCrystalLine will join their expertise, technologies, and resources. We will maximize each other’s skills while providing the pharmaceutical segment with solutions for chemical development and custom manufacturing of APIs,” says the CEO of ICROM, Pierfrancesco Morosini.

Merging capabilities

The two companies will jointly provide research and development capabilities, creating a unique team of over 20 scientists to share skills, equipment, expertise, and know-how.

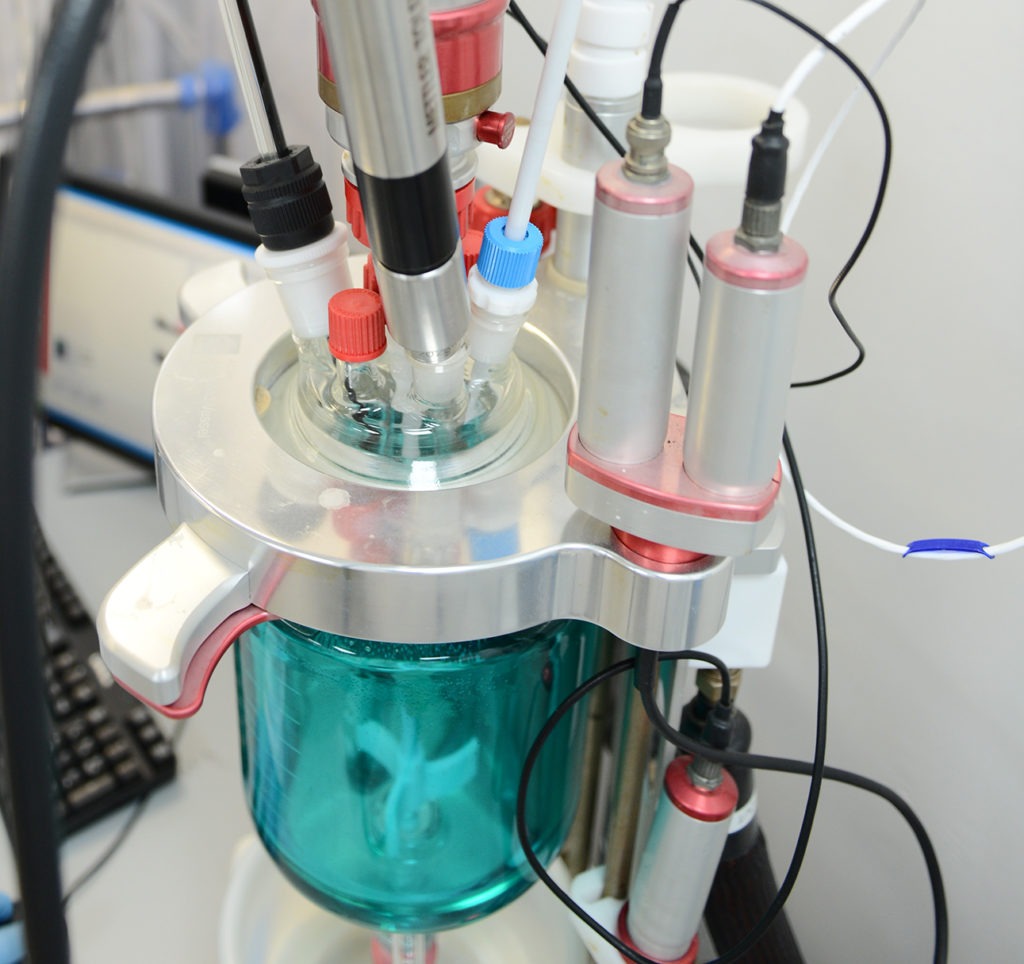

Lab spaces and cutting-edge tools will also be “connected”, making controlled reactors for site monitoring and crystallization process available and more accessible.

The use of the most recent advanced process analytical technology (PAT) on controlled reactors equipped with in-situ sensors, such as Crystal 16 or Mettler Toledo EasyMax working station, will allow R&D activities to be available from 4 mL on Crystal 16, to 10+ liter reactors, enabling a mechanism to design, analyze, and control pharmaceutical manufacturing processes through the measurement of critical process parameters (CPP), which affect critical quality attributes (CQA).

With the high containment system on point, thanks to stainless steel isolators, the R&D activities can be easily performed on highly potent APIs, up to OEB 5 (5 L controlled reactor).

Each project will be supported by both the analytical teams equipped with state-of-the-art technology such as:

- Xray Diffractometer, DVS Intrinsic, Malvern Morphologi G3, and Mastersizer 3000.

- Chromatography tools such as GC, GC-HS, HPLC-MS, UPLC-MS

The processes set-up at lab scale are then easily transferred through a joint tech-transfer team to the GMP workshops at ICROM, where the process can be up-scaled for pilot and validation manufacturing from a few kgs up to tons.

The reactions are constantly followed thanks to automated setting systems in equipment with multi-scale capacities from 25 L glass reactors, to stainless-steel, glass-lined and Hastelloy reactors from 500 L to 6,000 L and including a dedicated GMP unit for HPAPI manufacturing.

The solid-state consistency of industrial batches will be ensured by the team screening polymorphs, salt or co-crystals. The solid-state analyses (cGMP), including X-ray diffraction, particle-size distribution and surface area (BET), are available in-house for batch release.

Because of this alliance, the value of ICROM’s and PolyCrystalLine’s services will significantly increase, providing a strategic hub able to deliver a comprehensive service offer to the pharmaceutical market.

For further information please contact:

ICROM

Aline Sassi

aline.sassi@ICROM.com

LinkedIn: ICROM Srl

www.ICROM.com

PolyCrystalLine

Marco Glucini

marco.glucini@polycrystalline.it

LinkedIn: PolyCrystalLine SPA

www.polycrystalline.it