Pharma Innovation: AI in Drug Manufacturing

What is the potential of artificial intelligence (AI) in pharmaceutical manufacturing and what regulatory considerations come into play, including between CDMOs/CMOs and sponsor companies? The FDA has issued a discussion paper to highlight key issues and is seeking input from the industry.

AI in drug manufacturing

Late last month (February 2023), the US Food and Drug Administration (FDA) published a discussion paper, Artificial Intelligence in Drug Manufacturing, to outline areas for consideration and policy development identified by scientific and policy experts of the FDA’s Center for Drug Evaluation and Research (CDER) for the application of artificial intelligence (AI) in pharmaceutical manufacturing. The discussion paper includes a series of questions to stimulate feedback from the public, including CDER and the Center for Biologics Evaluation and Research (CBER) stakeholders. The FDA is seeking that input by May 1, 2023.

The discussion paper is part of a larger effort by the FDA in facilitating advanced manufacturing, a term that describes an innovative pharmaceutical manufacturing technology or approach that has the potential to improve the reliability and robustness of the manufacturing process and resilience of the supply chain. Advanced manufacturing can: (1) integrate novel technological approaches, (2) use established techniques in an innovative way, or (3) apply production methods in a new domain where there are no defined best practices. Advanced manufacturing can be used for new or currently marketed large- or small-molecule drug products.

The National Academies of Sciences, Engineering, and Medicine issued a 2021 report, Innovation in Pharmaceutical Manufacturing on the Horizon: Technical Challenges, Regulatory Issues, and Recommendations, highlighting innovations in integrated pharmaceutical manufacturing processes. These innovations could have implications for measurement, modeling, and control technologies used in pharmaceutical manufacturing. AI may play a significant role in monitoring and controlling advanced manufacturing processes.

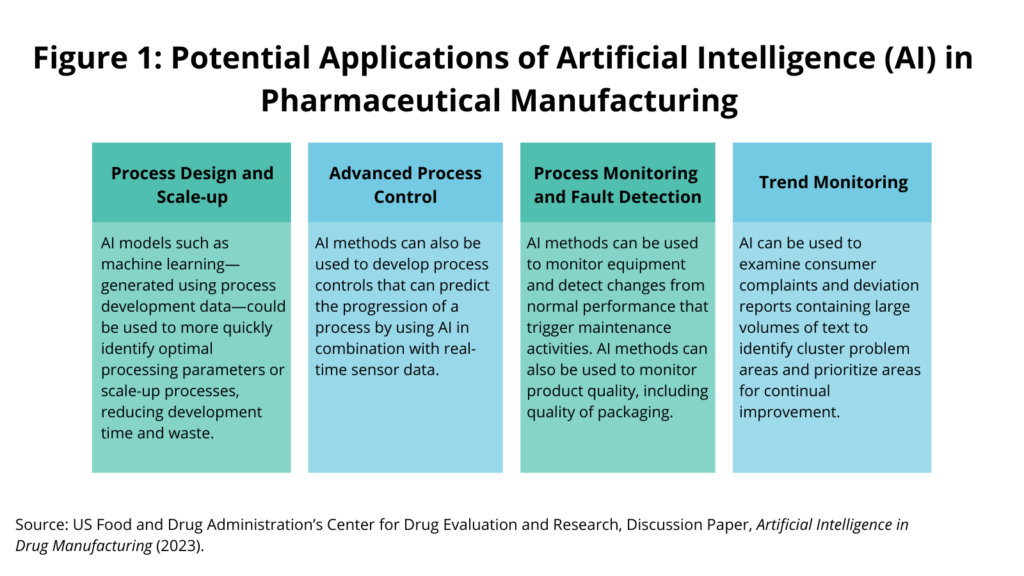

Figure 1 outlines examples of how AI can be applied in drug manufacturing as identified by the FDA through its interaction with the industry, including but not limited to optimizing process design and process control, smart monitoring and maintenance, and trend monitoring to drive continuous improvement. These examples are further detailed below.

Process design and scale-up: AI models such as machine learning—generated using process development data—could be used to more quickly identify optimal processing parameters or scale-up processes, reducing development time and waste.

Advanced process control (APC): APC allows dynamic control of the manufacturing process to achieve a desired output. AI methods can also be used to develop process controls that can predict the progression of a process by using AI in combination with real-time sensor data. APC approaches that combine an understanding of the underlying chemical, physical, and biological transformations occurring in the manufacturing process with AI techniques are expected to see increasing adoption and have already been reported by several pharmaceutical manufacturers, according to the FDA’s discussion paper.

Process monitoring and fault detection: AI methods can be used to monitor equipment and detect changes from normal performance that trigger maintenance activities, reducing process downtime. AI methods can also be used to monitor product quality, including quality of packaging (e.g., vision-based quality control that uses images of packaging, labels, or glass vials that are analyzed by AI-based software to detect deviations from the requirements of a product’s given quality attribute).

Trend monitoring: AI can be used to examine consumer complaints and deviation reports containing large volumes of text to identify cluster problem areas and prioritize areas for continual improvement. This offers the advantage of identifying trends in manufacturing-related deviations to support a more comprehensive root cause identification, as outlined by the FDA in its discussion paper. AI methods integrated with process performance and process capability metrics can be used to proactively monitor manufacturing operations for trends. These methods can also predict thresholds for triggering corrective and preventive action effectiveness evaluations.

Areas of consideration associated with AI in drug manufacturing

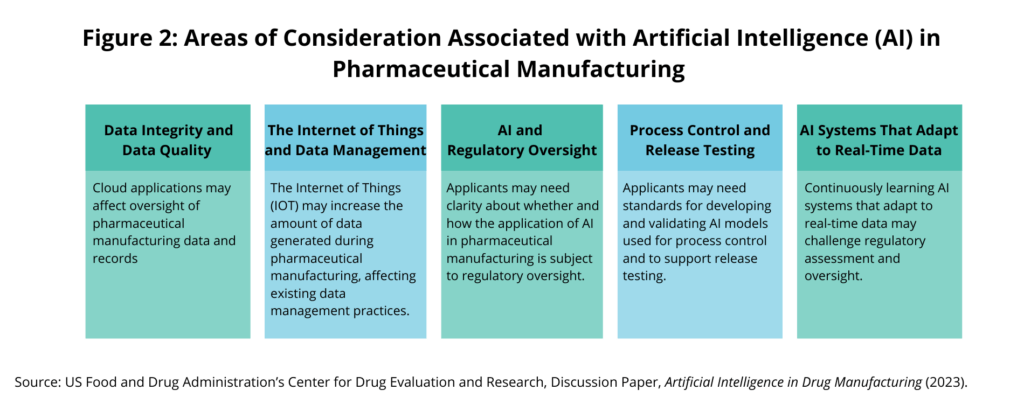

Figure 2 outlines five key areas to consider, both from a user and regulatory perspective, of AI in drug manufacturing, as raised by the FDA in its discusion paper. Further details are provided below.

Data integrity and data quality in cloud applications. Cloud applications may affect oversight of pharmaceutical manufacturing data and records. With evolving developments in cloud and edge computing, the software location involved in pharmaceutical manufacturing may change. For example, the software that controls execution may still be implemented close to the manufacturing equipment to ensure no impact on performance or security while other software functions that are not time critical could occur in the cloud (e.g., model updates, control diagnostics, and process monitoring analytics). Third=party data management systems could be used for functions that extend beyond data storage. For example, data stored in these systems may be analyzed by AI to support models for process monitoring and advanced process control.

The FDA emphasizes that data integrity and data quality must be ensured in these environments. While FDA allows the use of third parties for cGMP functions under appropriate oversight by the manufacturer, existing quality agreements between the manufacturer and a third party (e.g., for cloud data management) may have gaps with respect to managing the risks of AI in the context of manufacturing monitoring and control. During inspections, the FDA explains that this may lead to challenges in ensuring that the third-party creates and updates AI software with appropriate safeguards for data safety and security. Further, FDA inspection approaches for evidence gathering of records management may need to expand due to the complexity of managing third-party cloud data and models. For example, the ongoing interactions between cloud applications and process controls could complicate the ability to establish data traceability, create potential cybersecurity vulnerabilities, and require evaluation of the procedures in place to monitor data-integrity vulnerabilities during an inspection.

The Internet of Things (IOT) and data-management practices. The FDA’s discussion paper also points out that the Internet of Things (IOT) may increase the amount of data generated during pharmaceutical manufacturing, thereby affecting existing data-management practices.

Digitization of manufacturing controls may generate more information about a process and product. The increase in data may be in terms of both the frequency and the types of data recorded. There are regulations and guidance addressing the amount of data and metadata to be stored for each batch of drug product manufactured; however, if the raw data collected during the manufacturing process increase significantly, there may be a need to balance data integrity and retention with the logistics of data management. Also, there may be challenges in storing the data in a structured manner that enables retrieval and analysis to support an applicant’s decision-making. Moreover, as manufacturing equipment becomes interconnected into a network, maintaining stewardship, privacy, and security of such data generated by the equipment may pose a challenge to preserving product quality or maintaining pharmaceutical manufacturing.

AI in drug manufacturing and regulatory oversight. In its discussion paper, the FDA points out that applicants of drug filings (i.e., new drug applications and biologics license applications) may need clarity about whether and how the application of AI in pharmaceutical manufacturing is subject to regulatory oversight. For example, AI could be used in various manufacturing operations such as monitoring and maintaining equipment, identifying areas for continuous improvement, scheduling and supply-chain logistics, and characterizing raw materials. Applicants will need to understand the applications of AI in manufacturing operations that are subject to regulatory oversight (e.g., cGMP compliance, new drug or biologics license applications).

Process control and release testing. The FDA points out that applicants may need standards for developing and validating AI models used for process control and to support release testing. AI can be used in advanced process control applications to control manufacturing processes by adapting process parameters based on real-time data. Additionally, AI models can be used in conjunction within interrogation of in-process material or the final product to: (1) support analytical procedures foe in-process or final product testing, (2) support real-time release testing, or (3) predict in-process product quality attributes. There are limited industry standards and FDA guidance available for the development and validation of models that impact product quality, which can create challenges in establishing the credibility of a model for a specific use.

The underlying data shapes decisions made by the AI model. The FDA’s discussion paper points out that this can create challenges in avoiding unintended biases during model development and validation. AI models can also store knowledge gained during development for a specific use case and then apply it to a different but related use case to accelerate model development. Applicants and manufacturers may need clarity regarding how the potential to transfer learning from one AI model to another can be factored into model development and validation.

Real-time data in AI-based machine learning. The FDA points out in its discussion paper that continuously learning AI systems that adapt to real-time data may challenge regulatory assessment and oversight. In the current paradigm, models deployed in manufacturing (e.g., in-process controls, real-time release testing) are developed, validated, implemented, and updated as needed through the change-control process within the pharmaceutical quality system. AI models (e.g., machine learning-based models) can involve continuous learning wherein the model evolves over time as new information becomes available.

The FDA points out that It may be challenging to determine when an AI model can be considered an established condition of a process. It may also be challenging to determine the criteria for regulatory notification of changes to the model as a part of model maintenance over the product lifecycle. Applicants may need clarity on: (1) the expectations for verification of model lifecycle strategy and the approach for FDA’s examination of continuously updated AI control models during a site inspection, and (2) expectations for establishing product comparability after changes to manufacturing conditions introduced by the AI model, especially for biological products.

Seeking industry input

The FDA is seeking feedback from the industry and other stakeholder on eight key questions about the use and potential of AI in pharmaceutical manufacturing by May 1, 2023. These questions are outlined below.

- What types of AI applications do you envision being used in pharmaceutical manufacturing?

- Are there additional aspects of the current regulatory framework that may affect the implementation of AI in drug manufacturing and should be considered by FDA?

- Would guidance in the area of AI in drug manufacturing be beneficial? If so, what aspects of AI technology should be considered?

- What are the necessary elements for a manufacturer to implement AI-based models in a cGMP environment?

- What are common practices for validating and maintaining self-learning AI models and what steps need to be considered to establish best practices?

- What are the necessary mechanisms for managing the data used to generate AI models in pharmaceutical manufacturing?

- Are there other aspects of implementing models (including AI-based models) for pharmaceutical manufacturing where further guidance would be helpful?

- Are there other aspects of the application of AI in pharmaceutical manufacturing not that FDA should consider?