Continuous Manufacturing and Pharma: Where Does it Stand?

The bio/pharma industry is based on batch manufacturing, so how is the adoption of continuous manufacturing for drug substances and drug products progressing? A pending ICH guideline clarifies technical and regulatory issues. And, views from the industry.

Continuous manufacturing: where it stands

Although batch manufacturing is the dominant mode of manufacturing in the bio/pharmaceutical industry, continuous manufacturing has ongoing interest. The US Food and Drug Administration (FDA) has encouraged the adoption of innovation and new manufacturing technologies, including continuous manufacturing, a position that the FDA first put forth in 2002 with the agency’s initiative, Pharmaceutical Current Good Manufacturing Practices for the 21st Century, as a means to modernize pharmaceutical manufacturing and enhance product quality. This initiative included putting forth a science- and risk-based approach to pharmaceutical manufacturing and regulatory oversight through a quality-by-design approach as well as by encouraging new technologies, such as process analytical technology (PAT) and continuous manufacturing.

Support by the FDA and other regulatory agencies for continuous manufacturing is crucial. With the industry’s installed manufacturing base still in batch manufacturing and further investment required in equipment, analytical technology, such as PAT, and technical training for continuous manufacturing, the industry has been proceeding on a measured basis in adopting continuous manufacturing. However, with the potential for improved process control and reduced and more flexible manufacturing footprints, bio/pharmaceutical companies continue to evaluate continuous manufacturing for the production of both active pharmaceutical ingredients (APIs) and drug products.

A key step going forward will be the adoption of a new guideline, Q13, Continuous Manufacturing of Drug Substances and Drug Products, by the International Conference for Harmonization (ICH) of Technical Requirements for Pharmaceuticals for Human Use. ICH is a non-binding body that engages regulatory authorities and the bio/pharmaceutical industry to discuss scientific and technical aspects of drug registration, including quality considerations and good manufacturing practice (GMP), as a means to harmonize pharmaceutical regulation among regulatory bodies. Its membership includes the regulatory authorities from the US (the US Food and Drug Administration [FDA]), the European Union (European Commission), and Japan (Japan’s Ministry of Health, Labor and Welfare and Japan’s Pharmaceuticals and Medical Devices Agency). Its members further include regulatory authorities from Canada, Switzerland, China, Brazil, Singapore, and the Republic of Korea as well as industry associations, the Pharmaceutical Research and Manufacturers of America, the Biotechnology Innovation Organization, the European Federation of Pharmaceutical Industries and Associations, and Japan Pharmaceutical Manufacturers Association.

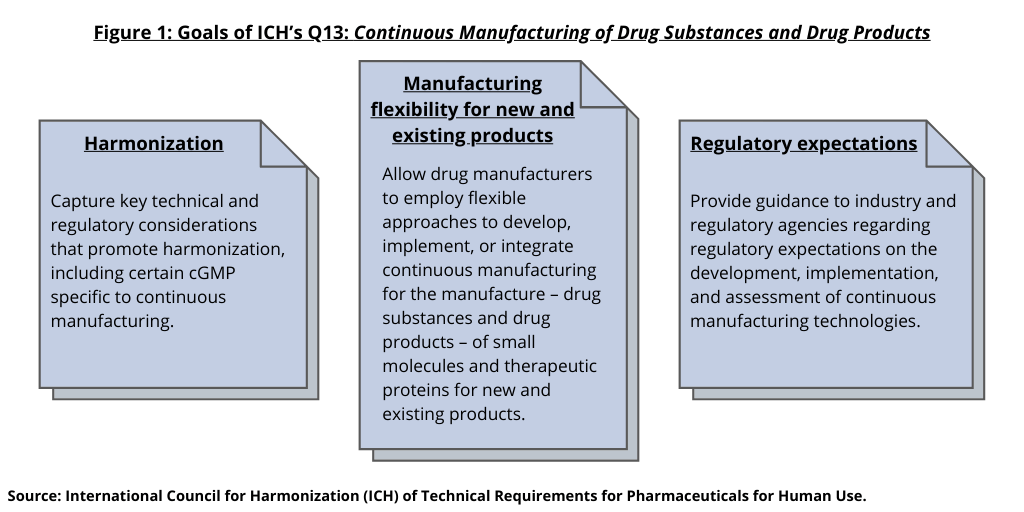

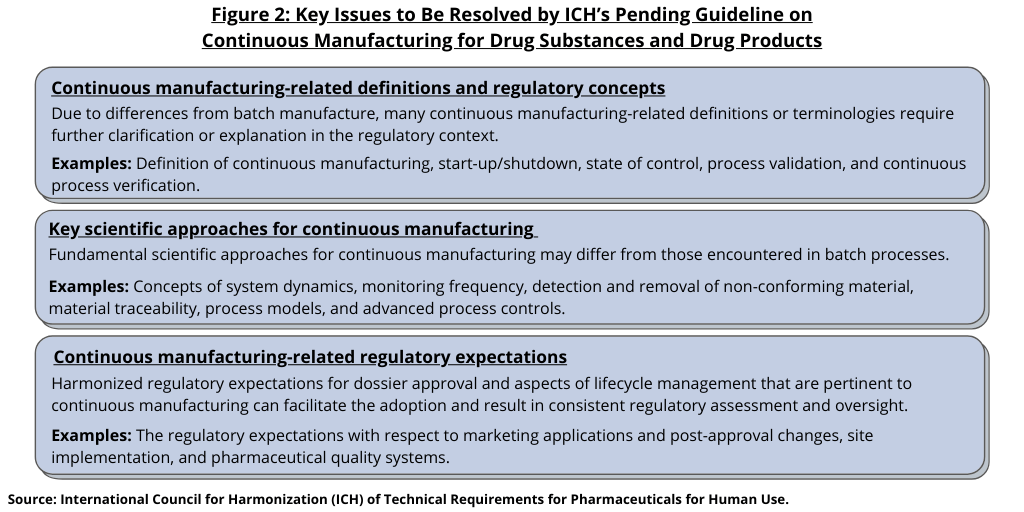

In 2018, ICH endorsed the development of a guideline on continuous manufacturing and since then, it has been working to develop a guideline on continuous manufacturing with a goal of finalizing the draft guideline and opening it to public consultation in 2021 and issuing a final guideline in November 2022. The new ICH guideline seeks to address several main issues (see Figure 1), such as capturing key technical and regulatory considerations that promote harmonization, including certain cGMP elements specific to continuous manufacturing. It also seeks to allow drug manufacturers to employ flexible approaches to develop, implement, or integrate continuous manufacturing for the manufacture of both drug substances and drug products for small molecules and therapeutic proteins for new and existing products. The ICH guideline will also provide guidance to industry and regulatory agencies regarding regulatory expectations on the development, implementation, and assessment of continuous manufacturing technologies used in the manufacture of drug substances and drug products. Figure 2 further specifies key items that ICH is seeking to resolve with the guideline: (1) continuous manufacturing-related definitions and regulatory concepts; (2) key scientific approaches for continuous manufacturing; and (3) regulatory expectations.

Once an ICH guideline is issued, its implementation depends on the adoption of the guideline by the participating regulatory agencies in ICH. The FDA issued a draft guidance, Quality Considerations for Continuous Manufacturing, in 2019, to specify key quality considerations and provide recommendations for how applicants should address these considerations in new drug applications (NDAs), abbreviated new drug applications (ANDAs), and supplemental NDAs and ANDAs for small-molecule, solid oral drug products that are produced via a continuous manufacturing process. The FDA’s draft guidance clarifies the agency’s current thinking regarding continuous manufacturing approaches to help resolve potential issues some companies may have as they consider implementation, such as concerns that use of new continuous manufacturing technology might impact the time the FDA takes to assess applications for new products and what is required from a regulatory view for switching from a batch to a continuous-manufacturing process for existing products.

In issuing the draft guidance, the FDA also outlined other steps it is taking to support the adoption of continuous manufacturing, which includes involvement of ICH’s guideline on continuous manufacturing. A final guidance on continuous manufacturing by the FDA is still under consideration and likely will be on hold pending the finalization of the ICH guideline.

Continuous manufacturing for small-molecule API manufacturing

|

|

Hongwei Yang, Ph.D. |

Continuous manufacturing may be applied in the manufacture of active pharmaceutical ingredients (APIs) (both small molecules and biologics) and drug products. To gain a perspective on its application in small-molecule API manufacturing, DCAT Value Chain Insights gained the perspective from the industry. Participating is Hongwei Yang, Ph.D., Senior Director and Head of Flow Chemistry, STA Pharmaceutical, a WuXi AppTec company (WuXi STA).

Q: From your experience, what type of projects do bio/pharma companies typically seek to use continuous manufacturing? Are they new drug projects as opposed to existing products? How about volume, do they tend to be for smaller-volume projects or potentially larger-scale projects?

Dr. Yang (WuXi STA): Currently, pharmaceutical companies are using continuous manufacturing as a good addition to the existing batch manufacturing method to tackle associated technical challenges. One of the key drivers is to manufacture reactions that are typically considered off-limits under the batch mode, including highly hazardous reactions and those involving extremely toxic or explosive reagents/intermediates. Pharmaceutical companies are also applying continuous manufacturing to achieve the new process windows to intensify the process, such as performing reactions at high temperature/pressure but using low-boiling-point solvent.

Recently, we have also witnessed increased interest from pharmaceutical companies in using continuous manufacture to scale up reactions involving novel energy input, including photochemical reactions, and electrochemical reactions. Continuous manufacturing is also seen as an efficient tool to minimize the scale-up risk, especially for reactions involving unstable intermediates/products.

For the projects that are actively applying continuous manufacturing, the majority of them involve novel drugs in need of a new process design. However, for existing products, there is a considerable effort needed to address the regulatory change control relevant to the shift of the manufacturing mode from batch to continuous.

Regarding the volume of projects, the majority of the flow-chemistry projects we manufacture are still in the early phase, which only require small-volumes. And we have several flow-chemistry projects that have moved from early phase to commercial stage with the final volume reaching tens of metric tons per year.

Q: What are potential advantages from a cost/technology perspective of continuous manufacturing/flow chemistry? What are potential challenges to overcome?

Dr. Yang (WuXi STA): For early-phase projects, the major advantage of flow chemistry is to enable the manufacturing of certain types of reactions for a speedy supply of clinical campaigns that are difficult in batch mode, so the re-design of the synthetic route is avoided. Also, the mobile nature of the key flow-chemistry units allows the transfer of manufacturing units in different sites or even countries, thereby streamlining the process transfer and improving the robustness of the supply chain.

From a cost perspective, at the beginning, there may be a limited advantage considering more efforts needed for developing the flow-chemistry process and the new CAPEX investment needed for the production unit. But, when the projects evolve to a late campaign with a high-volume need, the cost advantage over batch mode would be capitalized when considering the opportunities to achieve a higher yield, to enable the use of more cost-competitive reagents, to reduce the quantity of expensive reagents/catalysts used, and to minimize batch failures.

The potential challenges may come from the technical side and regulatory sides. Technically, the requirement for the robustness of material-delivery systems would be very high for continuous processing, and so far, we still don’t have systems that could reliably deal with processes for certain media with different physical properties (e.g. solids, suspensions, high viscous materials, etc.). From a regulatory perspective, even though several guidelines have been published by different regulatory agencies, there is still limited experience for the actual implementation in the industry; thus, those guidelines may need to be continuously updated to include the new findings/observations from real cases.

Q: The industry’s installed production capacity is based on batch manufacturing. How do you see continuous manufacturing’s adoption progressing now and over the next several years? In your opinion, what will it take to further advance the adoption of continuous manufacturing in the industry?

Dr. Yang (WuXi STA): We would not expect a complete shift from batch manufacturing to continuous manufacturing within a short period. A viable option could be the adoption of a hybrid approach, where continuous manufacturing is implemented in selected projects and unit options to address the associated technical challenges under the batch mode. With the advancement of continuous processing equipment and on-line analysis equipment, continuous manufacturing will then take a much larger role in the manufacturing of pharmaceuticals.

I think CDMOs would play a vital role in advancing the adoption of continuous manufacturing, mainly taking advantage of the platform nature of these companies. Their experience and expertise could be continuously improved from all types of projects from different clients, but the cost burden in the early implementation of continuous manufacturing can be shared by all the customer projects that are manufactured from the same production lines.