Executive Order Advances US-based Drug Production

President Donald Trump issued an executive order late last week (August 6, 2020) to increase US-based production and federal procurement of essential medicines, medical countermeasures, and critical inputs. What does the executive order authorize, and what is the impact on the pharma industry?

Executive order for US-based drug production

The move to re-shore US-based drug manufacturing took a step forward last week (August 6, 2020) with the issuance of an executive order by President Donald Trump. The order sets forth the policy goals and authorization by certain federal departments and agencies, including the US Department of Health and Human Services (HHS) and the US Food and Drug Administration (FDA), to increase US-based production and federal procurement of essential medicines, medical countermeasures, and critical inputs. For purposes of the executive order, “essential medicines” are defined as those necessary for the US and identified by the FDA Commissioner as such. “Critical inputs” refer to active pharmaceutical ingredients (APIs), API starting materials, and other ingredients of drugs and components of medical devices that the FDA Commissioner determines to be critical in assessing the safety and effectiveness of essential medicines and medical countermeasures. Medical countermeasures are FDA-regulated products (biologics, drugs, devices) that may be used in the event of a potential public health emergency stemming from a terrorist attack with a biological, chemical, or radiological/nuclear material or a naturally occurring emerging disease.

”The United States must protect our citizens, critical infrastructure, military forces, and economy against outbreaks of emerging infectious diseases and chemical, biological, radiological, and nuclear (CBRN) threats,” said President Trump in the executive order. “To achieve this, the United States must have a strong Public Health Industrial Base with resilient domestic supply chains for Essential Medicines, Medical Countermeasures, and Critical Inputs deemed necessary for the United States. These domestic supply chains must be capable of meeting national security requirements for responding to threats arising from CBRN threats and public health emergencies, including emerging infectious diseases such as COVID-19. It is critical that we reduce our dependence on foreign manufacturers for Essential Medicines, Medical Countermeasures, and Critical Inputs to ensure sufficient and reliable long-term domestic production of these products, to minimize potential shortages, and to mobilize our Nation’s Public Health Industrial Base to respond to these threats.”

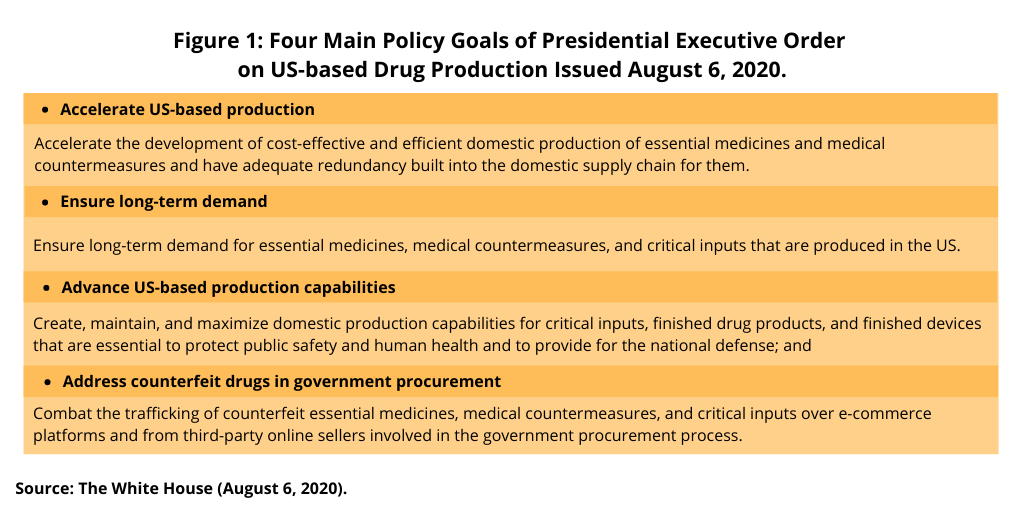

To meet those objectives, the executive order puts forth four main policy goals (see Figure 1). These goals are: (1) accelerate the development of cost-effective and efficient domestic production of essential medicines and medical countermeasures and have adequate redundancy built into the domestic supply chain for them; (2) ensure long-term demand for essential medicines, medical countermeasures, and critical inputs that are produced in the US; (3) create, maintain, and maximize domestic production capabilities for critical inputs, finished drug products, and finished devices that are essential to protect public safety and human health and to provide for the national defense; and (4) combat the trafficking of counterfeit essential medicines, medical countermeasures, and critical inputs over e-commerce platforms and from third-party online sellers involved in the government procurement process.

Implementation of the executive order

The executive order outlines authorization for federal departments and agencies to increase US-based production of essential medicines, medical countermeasures, and critical inputs and to limit federal procurement for such products to be made in the US (see Table I at the end of the article). To mitigate supply-chain vulnerabilities, the HHS Secretary is authorized, either through revising regulations or guidance, to require certain information from drug manufacturers. This information would include: (1) the sources of finished drug products, finished devices, and critical inputs; (2) the use of any scarce critical inputs; and (3) the date of the last FDA inspection of the manufacturer’s regulated facilities and the results of such inspection.

The executive order also seeks to remove certain regulatory barriers to US-based drug production for essential medicines, medical countermeasures, and critical inputs by authorizing the HHS Secretary to review FDA regulations to determine if they may be a barrier to domestic production of these products and to advise the President whether such regulations should be repealed or amended. The executive order also provides further authorization for the HHS Secretary, through the FDA Commissioner, with regard to inspections and facility approvals and for facilitating the use of advanced manufacturing, such as continuous manufacturing and 3-D printing (see Table I at the end of the article). Specifically, the executive order authorizes the HHS Secretary through the FDA Commissioner to do the following: (1) accelerate FDA approval or clearance of domestic producers of essential medicines, medical countermeasures, and critical inputs; (2) negotiate with countries to increase site inspections and increase the number of unannounced inspections of regulated facilities; (3) refuse admission of imports of essential medicines, medical countermeasures, and critical inputs if the facilities in which they are produced refuse or unreasonably delay an inspection; and (4) issue guidance with recommendations for the development of advanced manufacturing techniques (see Table I at the end of the article). The executive order also authorizes the Environmental Protection Agency to take all appropriate action to identify relevant requirements and guidance documents that can be streamlined for advanced manufacturing facilities and domestic production of critical inputs by accelerating siting and permitting approvals.

While facilitating US-based drug production, the executive order does provide for certain exemptions. It allows for a broad measure to exempt actions that would not be in the public interest. It more specifically exempts products not produced in the US in sufficient and reasonably available commercial quantities and of a satisfactory quality of if their application would cause the cost of procurement to increase by more than 25%. Also, federal procurement of drugs in the US is more limited than in other Western governments, for example, only by certain federal departments and agencies, such as the Veterans Health Administration and the Department of Defense.

Industry feedback

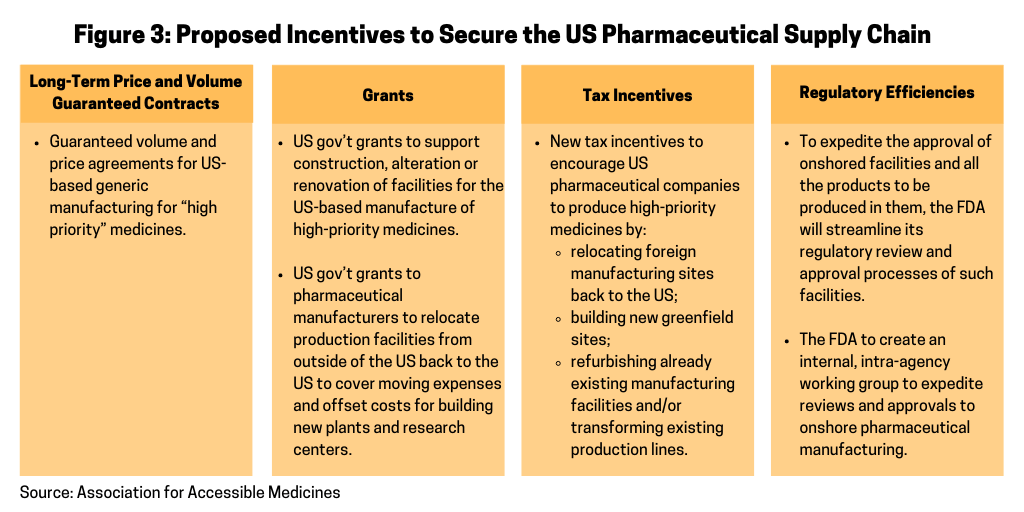

Industry feedback to the executive order has been mixed. The Pharmaceutical Research and Manufacturers of America (PhRMA), which represents innovator, research-based pharmaceutical companies, criticized the executive order. The Association for Accessible Medicines (AAM), which represents generic and biosimilar developers and manufacturers, offered measured support for the executive order. In late April (April 2020), the AAM had issued its own proposal for facilitating the re-shoring of US drug production for essential medicines, A Blueprint for Enhancing the Security of the US Pharmaceutical Supply Chain, a six-element framework that lays out actions that the federal government could take to ensure a consistent supply of critical pharmaceuticals (see Figures 2 and 3). The executive order includes certain elements of that blueprint, such as authorizing the HHS Secretary to identify a list of essential medicines to be produced in the US, but it falls short in providing financial incentives to drug manufacturers to re-shore drug manufacturing.

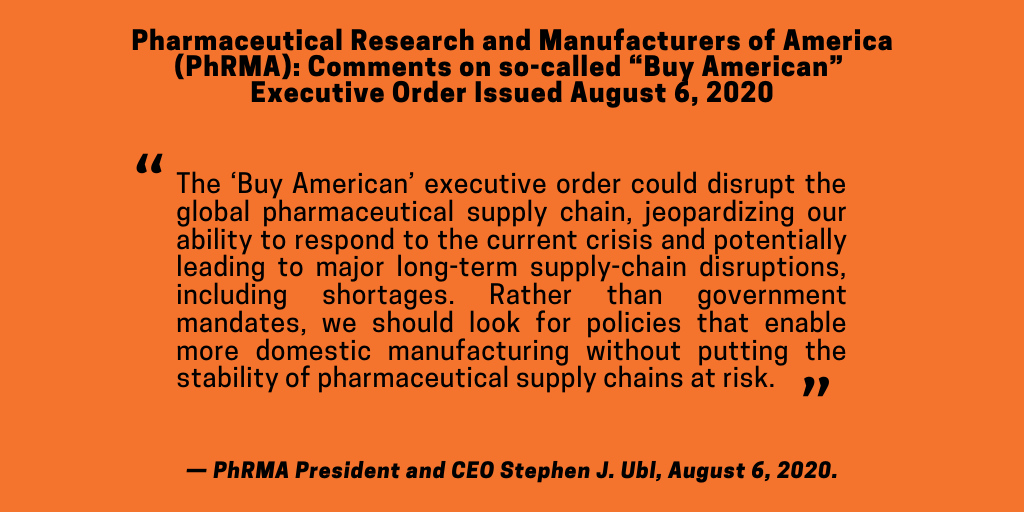

PhRMA voiced objections to the executive order, particularly in light of four other executive orders issued last month (July 2020) on drug pricing, including one that tied US drug pricing to international drug pricing. “The administration is forcing biopharmaceutical companies to shift their critical attention and resources away from COVID-19 work to focus on making substantial changes to their business models necessary to comply with this and other recent executive orders,” said PhRMA President and CEO Stephen J. Ubl in a August 6, 2020 statement. “Increasing US manufacturing of medicines is a laudable goal, but it cannot happen overnight and should not come at the expense of medical innovation or Americans’ access to the medicines they need.”

Ubl said that mandates for US-based drug production and linking US drug pricing to international drug pricing run counter to each other. “The recent executive orders also contradict and undermine each other, creating chaos in an industry that is on the frontlines of fighting COVID-19,” said PhRMA’s Ubl in his August 6, 2020 statement. “With today’s [August 6, 2020] ‘Buy American’ executive order, the administration effectively is taking the unprecedented step of mandating manufacturing of medicines in the United States. Yet at the same time, through the ‘most favored nation’ executive order, the administration is creating a huge disincentive to invest in US biopharmaceutical research and manufacturing. Together, the result is less investment in US innovation and the potential for major long-term supply-chain disruptions—the opposite of what America needs right now. None of these executive orders will help patients access or afford their medicines.”

Instead, Ubl is recommending ways to enable more domestic drug production in the US without explicit mandates to do so. “The ‘Buy American’ executive order could disrupt the global pharmaceutical supply chain, jeopardizing our ability to respond to the current crisis and potentially leading to major long-term supply chain disruptions, including shortages,” said Ubl in his statement. “Rather than government mandates, we should look for policies that enable more domestic manufacturing without putting the stability of pharmaceutical supply chains at risk.”

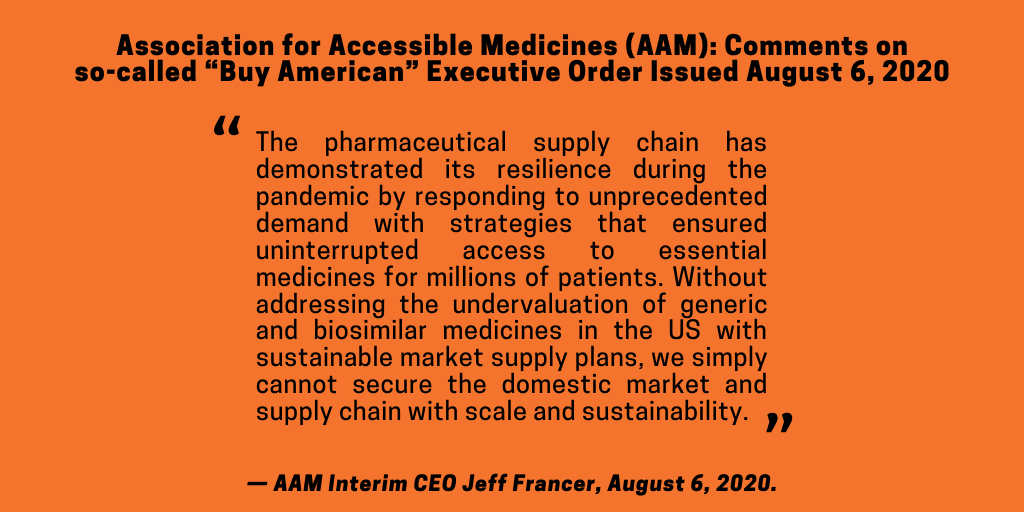

On the generics side on the industry, the AAM said that it continues to work with the Administration and Congress on its blueprint to increase domestic drug production in the US. It provided measured support for the executive order but also emphasized the need to do more to increase drug manufacturing in the US.

“The pharmaceutical supply chain has demonstrated its resilience during the pandemic by responding to unprecedented demand with strategies that ensured uninterrupted access to essential medicines for millions of patients,” said AAM Interim CEO Jeff Francer in an August 6, 2020 statement. “Without addressing the undervaluation of generic and biosimilar medicines in the US with sustainable market supply plans, we simply cannot secure the domestic market and supply chain with scale and sustainability.”

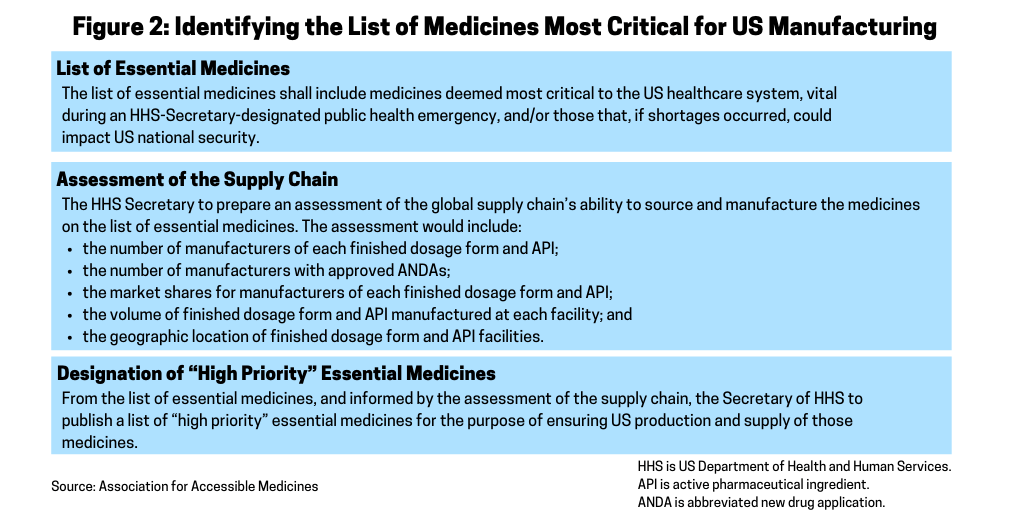

Similar to the executive order, a key part of the AAM’s blueprint is to provide the HHS Secretary the authority to establish a list of essential medicines for the US that includes medicines deemed most critical to the US healthcare system during an HHS Secretary-designated public health emergency and/or those that, if shortages occurred, could impact US national security. Unlike the executive order, the AAM blueprint recommends that the list of essential medicines would be subject to a 60-day public comment period. Also, the AAM blueprint calls for a prioritization of essential medicines, or a high-priority list of essential medicines.

While the executive order and the AAM blueprint both specify an assessment of supply-chain vulnerabilities, the AAM blueprint is more specific by recommending that the HHS Secretary prepare of global assessment of the drug supply chain with certain key evaluations (see Figure 2). That assessment would include: (1) the number of manufacturers of each finished dosage form and API; (2) the number of manufacturers with approved abbreviated new drug applications; (3) the market shares for manufacturers of each finished dosage form and API; (4) the volume of finished dosage form and API manufactured at each facility; and (5) the geographic location of finished dosage form and API facilities.

Although the executive order seeks to increase regulatory flexibility, also a goal in the AAM blueprint, the AAM blueprint is more specific in recommending tax incentives, grants, and long-terms contracts and volume guarantees (see Figure 3) as a means to encourage pharmaceutical manufacturers to repatriate pharmaceutical manufacturing to the US and to offset the costs for doing so. AAM’s proposal specifies that within six months of the completion of the list of “high priority” medicines, the HHS, acting through the Office of the Assistant Secretary for Preparedness and Response under the HHS, would seek new and specific proposals from pharmaceutical manufacturers to determine how individual companies can help secure the US pharmaceutical manufacturing base for priority medicines. Proposals would include the list of specific finished dosage forms and APIs the company proposes manufacturing in the US and the specific type of incentives necessary to make the facilities economically viable. The HHS would be authorized to make such incentives available as described in Figure 3.

Table I: Manufacturing and Procurement Requirements from Executive Order on US-based Drug Manufacturing Issued August 6, 2020

| Maximizing domestic production via federal procurement |

|

| Supply-Chain Vulnerabilities: Reporting Requirements |

|

| FDA: Advanced manufacturing and facility inspections |

|

| List of Essential Medicines |

|

| US Department of Defense-Specific Essential Medicines |

|

| Streamlining EPA regulatory requirements |

|

| Federal agency reporting requirements |

|

|

MCM is medical countermeasure. OBM is the Office of Management and Budget. HHS is the US Department of Health and Human Services. FDA is the US Food and Drug Administration. EPA is Environmental Protection Agency |

|

Source: The White House, “Executive Order on Ensuring Essential Medicines, Medical Countermeasures, and Critical Inputs Are Made in the United States,” issued August 6, 2020. |